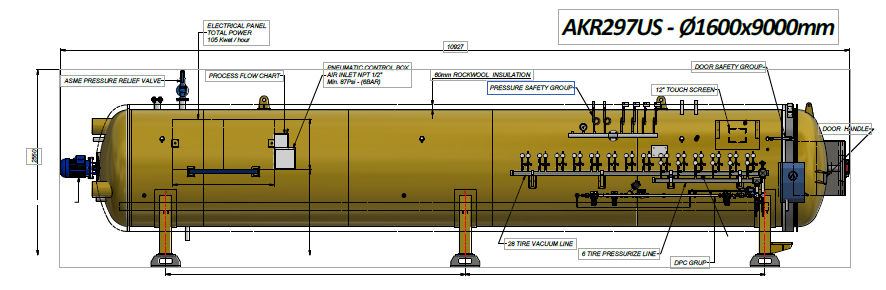

AKR297US Model: Cutting-edge Technology Tailored For The USA Market

As one of the world's leading autoclave manufacturers, Akarmak presents a range of innovative features with the AKR297US model, designed to meet the needs of its customers in the American market. This model is designed to fully meet the requirements of tire retreading facilities in the USA, with high capacity and economic scale.

Features That Minimize Process Costs

The AKR297US stands out with its features that minimize process costs. This model includes 28 active vacuum ports for radial tires and 6 active vacuum ports for bias tires. These features provide high tire capacity, reducing costs per process. Additionally, compared to traditional tire retreading autoclaves, it offers faster curing with larger fan capacity and wide air channels.

Thanks to the TC on the vacuum collector, quick intervention is possible in case of vacuum leaks during the process, minimizing curing problems, which is one of the biggest issues for retreading facilities in America.

User-Friendly and Safe Design

The AKR297US features a user-friendly and process-safe design, providing great convenience with its 12” Siemens HMI panel and long vacuum hoses. The extra thermocouple on the vacuum collectors allows quick intervention in case of vacuum leaks during the process, while the pneumatic door locking mechanism provides additional safety. The long vacuum hoses allow the operator to make vacuum connections to tire envelopes without entering the autoclave. Additionally, the AKR297US control system allows for remote online connection.

High-Level Safety

The AKR297US is a highly safe device with an ASME U Stamp certification. Vacuum collectors made of stainless steel provide long-term and safe use. These features demonstrate the superiority of the AKR297US model in terms of safety and durability.

Thanks to the advanced technology of the AKR297 US model, it perfectly adapts to the industrial needs of the United States, setting a new standard in autoclave technology with its user-friendly design.

In addition to the ASME (U, S & R) certification required for the USA, Akarmak has the capability to produce autoclaves according to the main certifications such as PED 2014/68/EU CE (Europe), EAC (Russia and Former Soviet Countries), as well as country-specific certifications for Canada (CRN), Australia (AS 1210 – 1997), Korea (Kosha), and Japan (Mhlw).

Akarmak, together with Akarmak USA Inc. based in the USA and Shamrock Marketing Inc. (www.shamrockmarketinginc.com), a leading supplier and spare parts and service partner in the tire retreading industry, offers TBR and OTR autoclaves to customers in the USA and Canada.

Founded in 1990, Akarmak is a global and leading company in autoclave products, offering autoclave products to customers in the fields of composites (aerospace and defense), glass lamination, rubber, tire retreading, building materials, and sterilization. In addition to many projects realized in America, Akarmak has sold its autoclave products to more than 70 countries worldwide.